Chains

I found a chain with different length in the system than I have on my bike. Why?

Which connecting links are supplied for chains?

Operating and maintenance of motorcycle chains

There is a lot of myths and guaranteed advices about maintenance of chain. But the maintenance is not a science if you know what to do. We serve you a couple of tips for the maintenance of your chain.

Choice and labeling chains

Numbers in the names (e.g. 428, 520, 530 etc.) mean proportions, tolerances, minimum tensile strength or other specifications by Japanese industry standards JIS (similar to ISO etc.)

First number

4,5,6 mean distance between chain pins = spacing

Originally, this numbers specified spacing in eights of inches, so the chain series 400 had a spacing of ½ inch, but today metric units are used, so chain series 400 has a spacing of 12,7 mm, 500 – 15,875 mm, 600 – 19,05 mm.

Second and third number

They mark a width of chain measured between inner surfaces of inner sideways pads. Marking ending with „20“ (420, 520,…) means a width of 6,35 mm between pads (2/8 inch). If the number ends with „25“ or „28“, the width is 7,94 mm (2,5/8 inch). If the number ends with „30“ or „32“, the width is 9,53 mm (3/8 inch).

Because a wider chain has of course higher strength, second and third number also mark strength of the chain relative to other chains with the same spacing. Higher numbers mean higher strength, e.g. chain 525 is stronger than 520. This additional strength is achieved because of a bigger rolling pin.

ATTENTION! This does not mean that all 520 chains have the same strength, it depends also on the width of pads and material. Chains of the same proportions can be different type and vary in additional marking, which varies according to the manufacturer (e.g. at EK 520SRO5 and SROZ)

How to choose the chain then?

It is necessary to replace your old chain with the same proportions chain, this means with the same JIS number. It should correspond with the chain mounted in the manufacture, but there are of course alternatives that are better and cheaper than the standard one, the result is higher durability and a period of change. Replacing sealed chain with non-sealed is not recommended, except special cases such as race use

Lubricating and cleaning of the chain

Cleaning the non-sealed chain is easier, we can do it with wire or other rough brush or suitable cleaner. At the non-sealed chain, we have to pay attention especially on sealing rings and because of that, it is necessary to avoid some things. Never clean the sealed chain with pressure washer, vapour cleaning, wire brushes or solvents such as petrol, alcohol, contact spray or acetone (these solvents can damage the sealing rings). Cleaning with the technical cleaning sprays, which require rinsing with water, can lead to a corrosion and because of that, using this products is not recommended. The best is of course special cleaning facility, which is supplied by most of oil companies. It is ideal to use a chain washer, e.g. Kettenmax

Non-sealed chains,

especially those used off-road and for the race use should be cleaned and lubricated a lot more frequently. Non-sealed chains can be lubricated with any quality chain lubricant or e.g. gear oil with specification SAE 80/90.

Sealed chains

should be lubricated each c. 500 km with lubricants specially marked as suitable for O-ring chains (not damaging sealing). A quality chain lubricant should fit well on the chain and have good penetration characteristics to go deep between bush and roller pins.

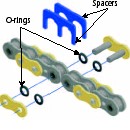

O – rings or QUADRA-X rings used e.g. at EK chains only seal lubricant applied at manufacturing between pins and bushes. As at the other ones, the chain needs to be lubricated regularly between bushes and roller pins to legthen its lifetime.

There is a lot of discussions about where to spray the lubricant. How is it then?

The sealed chain is filled with the lubricant inside already from the manufacture, which is sealed with the sealing rings. If the rings are allright, the lubricant can´t escape and the impurities can´t get inside. If they are damaged, you can´t get the lubricant inside properly and the chain is condemned to a change.

Where to lubricate then?

Sliding surface between the roller pin and the bush is not sealed and has relatively big play. Roller pin is also a contact point between the chain and teeth of the sprocket. The outer part of the roller pin has to be oily only for running on and off the pin from the space between teeth. Sometimes there is a wrong idea that the roller pin rotates on tooth. But the motion happens between the roller pin „standing in the tooth space“ and the bush, which rotates in the roller pin. This is the right place for lubrication, it is necessary to get the lubricant there. The lubricant gets from this space with a centrifugal force while operation after its warming up. The best way to deliver the lubricant there is with the special spray.

Besides this most important place, it is important to lubricate slightly also a surface of the roller pin. On the other places of the chain, the lubricant has only anticorrosive sense.

We recommend to wipe new chain with dry, clean rag before installation on motorcycle. The original lubricant is sticky, not to fly out because of the centrifugal force. Thanks to this, dust catches on the surface of the chain and together with the lubricant creates an abrasive paste. After using the dry rag to wipe, the chain remains preserved enough, but is not sticky anymore. During operation, the lubricant warms up and thanks to centrifugal force flies out, because of that is important to lubricate continuously. Before lubricating we recommend to get the chain rid of the dust. Lubrication oils in spray are very cappilary lifty so they can carry dust to lubricated places, which means the abrasive paste again.

If you use the chain cleaner, apply the lubricant after c. 10-20 minutes, when the cleaner´s solvents evaporate.

The change of the chain

When is it the best to change and how to recognize that?

The fastest and simplest way to recognize, that you need a new chain, is that you grab one link, which is in contact with the rear sprocket. If you can pull the link more than about a half of the tooth of the sprocket, it is time for the new chain. More reliable and exact is to use special gauges for chains.

We can also follow the chain tensioner on the rear arm. If you regularly set the chain play during prescribed maintenance of the motorcycle, than your chain is at the end of its lifetime, when the rear axle or tensioner reaches the last mark. Always follow the manual of your motorcycle.

If your chain creates an inappropriate noise when riding, or you find out that rear wheel is covered with the dirty lubricant, it is very probable that the chain has to be replaced. When you clean the chain, pay attention to the close check-up of the seals and roller pins. If you find some damaged or broken pin, change the chain immediately.

Is it always necessary to change sprockets?

To recognize the level of mechanical wear of the sprocket teeth you would have to have special measuring device. If you don´t use the chain for the race use and ride thousands of kilometers with it, it is probable that also teeth will be seriously worn. Due to the fact that the price of sprockets is a fraction of the price of the quality chain, it is worth changing sprockets always with the chain. Using more chains on one set of sprockets is meaningful only at the race use.

What is the right tension of the chain?

You can generally consider as usual that tension, when the sag is between 35-45 mm. But you should always follow the vehicle manufacturer´s instructions.

Is there some period of running in the newly mounted chain?

The new chain does not have any period of running in concerning the transfer of the power. But it is important to check the tension after first 100 km and then every 300 km until 1000 km.

EK chains with the unique technology ZST (Zero Stretch Technology) don´t have to be tensioned for the first 1000 km at all!!!

Defects of chains

Is it possible, that the damage is caused because of the manufacturing defect?

Chains of the well-known brands, which are used by the world leading motorcycle manufacturers in the production are developed and made with the newest technologies and are also subjected under strict quality control. It is not probable that chain like this would have some manufacturing defect. Even the power of the strongest motorcycles and ATVs does not reach over the strength of high-tech quality chains. On condition that you have chosen the right complements, the most probable reason is wrong installation, maintenance, incorrect setting of the chain play, wrong length etc. In case of the damage of your chain, turn to the specialized service, that should reveal the reason of the damage and recommend you the reparation. Technics ,business and service partners of the company Motopoint are regularly trained in the chain problems and its use. Don´t hesitate to turn on them.

You can find contacts on the headline in the section Business partners.

Pretraživanje po motociklu

Katalog po proizvodima

- << sve kategorije >>

- * Close-out sale

- * Električni motori i skuteri TORROT

- * HORWIN električni skuteri i motocikli

- Alati i oprema za servise

- Alat JMP

- Alat RMS

- Alate EK

- Alati za održavanje MOTION STUFF

- Alati za ovjes K-TECH

- Alati, popravak

- D.I.D alati za lance

- Fork Tools SKF

- Fork seal tools ARIETE

- Hour meter MOTION STUFF

- LV8 Stražnji jednoručni stalci

- LV8 dizala i pribor za motocikle

- LV8 garažna oprema i alati

- LV8 oprema za radione

- LV8 stajala

- LV8 stalci s adapterima

- MX Stands MOTION STUFF

- Motorcycle lift MOTOPOINT “made in Italy”

- Moving Stands LV8

- Održavanje PUIG

- Ramps MOTION STUFF

- Servisni set za skutere

- Stajala PUIG

- Stands MOTION STUFF

- Tire repair kit (travel set) MOTION STUFF

- Tools JT

- Tools KYB

- Tools LEVIOR

- Tools for tyres MOTION STUFF

- Dodatna oprema

- 'Grip'' naljepnica PUIG

- 4racing dodatna oprema

- Accessories 70ty

- All Balls other goods

- Athena ostali proizvodi

- CYCRA dodatna oprema

- Cevna zaštita za motorne CUSTOMACCES

- Crash protections

- Dodaci CROSS-PRO

- Dodaci CUSTOMACCES

- Dodaci PUIG

- Front boards protections PUIG

- Hi-Tech dijelovi za maxi skuterje PUIG

- K-TECH naljepnice

- MUC-OFF Promotional & Events

- Mirror hole screw plug PUIG

- Motocross dodaci MOTION STUFF

- Nastavki za dvižno stojalo PUIG

- Navlake za motore RMS

- Nosač reg. tablice PUIG

- Odjeća PUIG

- Ostali proizvodi JMT

- Ostali proizvodi Lucas

- Ostali proizvodi RMS

- Other parts ARIETE

- Poklopac šasije PUIG

- Promotional items ARIETE

- Rearview mirrors caps with turn lights PUIG

- Reinforcement supports PUIG

- Rukohvat za sovozača PUIG

- Šaraf PUIG

- Spare parts PUIG

- Sustavi vezanja i prtljage MOTION STUFF

- Tank grips ARIETE

- Tank protectors ARIETE

- Trakovi za felgu PUIG

- VENHILL dodaci

- VIBRAM Rubber Frame Pads

- Zaštita PUIG križeva

- Zaštita poklopca rezervuara PUIG

- Zaštita rezervoara PUIG

- Zaštita za rezervoar (tankpad) MOTION STUFF

- Zaštita zadnje vilice (vaga) POLISPORT

- Zaštitnik za ogrebotine PUIG

- Zatvorite čepove za ulje PUIG

- Zimski dodaci PUIG

- Elektrika

- Akumulatori i pribor

- Akumulatori BS-Battery

- Akumulator bez održavanja (Maintenance Free) BS-BATTERY

- BS-BATTERY Conventional, Konvencionalna baterija BS

- Konvencionalni akumulator BS-BATTERY (uključujući paketa kiseline)

- Litijeve baterije BS-BATTERY

- Tvorničko aktiviran akumulator SLA Max BS-BATTERY

- U tvornici aktivirani SLA akumulatori BS-BATTERY

- Akumulatori JMT

- BS-Battery punjači baterija

- Baterije YUASA

- Baterijski monitori JMP

- Battery chargers in ACTION FULBAT

- Booster FULBAT

- FULBAT baterije

- Lithium-ion baterije JMT

- Power box BS-BATTERY

- Punjači za baterije JMT

- Akumulatori BS-Battery

- Alternatori i generatori

- Brzinomjeri RMS

- CDI

- Dijelovi paljenja

- Dodatna svjetla PUIG

- E-chokes TNT

- Elektronički dijelovi

- Hupe RMS

- Kablovi RMS

- Kondenzatori RMS

- Kontaktni prekidači RMS

- Osigurači RMS

- Ostali električni dijelovi

- Otpornici RMS

- Pomoćna svjetla CUSTOMACCES

- Posledno svijetlo PUIG

- Prednja svjetla RMS

- Prekidači

- Radiator fan motor ARROWHEAD

- Regulatori i ispravljači

- Releji RMS

- Senzori RMS

- Solenoid repair kits All Balls

- Starter i dijelovi

- Stators

- Stop lights CUSTOMACCES

- Stražnja svjetla RMS

- Svijetla CUSTOMACCES

- Svijetla PUIG

- Svjećice

- TEXA diagnostika

- TEXA updates

- Žarulje RMS

- Žmigavac CUSTOMACCES

- Žmigavac i pribor

- Akumulatori i pribor

- Filteri i usisni dijelovi

- Gume

- Ispušni sustavi

- ATHENA ispuhi

- Athena ispušna vuna

- Auspušni nosači PUIG

- Exhaust wraps MOTION STUFF

- GPR

- Bolt-on silencers GPR

- Cafè Racer Transformation GPR

- Decat systems GPR

- Double Bolt-on silencers GPR

- Double Full Line exhausts GPR

- Double Slip-on exhausts GPR

- Full exhaust systems GPR

- Link pipe 4in1 Cafè racer transformation GPR

- Mid-full system exhausts GPR

- Other parts GPR

- Silencers without link pipes GPR

- Slip-on exhausts GPR

- Ispušne opruge JMP

- Izolacijska vuna EBC

- Kamena vuna za ispuh RMS (Rock wool RMS)

- MIVV

- DAKAR - MIVV exhausts

- DELTA RACE - MIVV ispuh

- GP PRO - MIVV ispuh

- HR-1 - MIVV exhausts

- MK3 - MIVV exhausts

- MOVER line - MIVV exhausts

- POWER cjeli ispušni sustav - MIVV

- Rezervni dijelovi MIVV

- SPORTLINE - MIVV ispuh

- SR-1 - MIVV exhausts

- STR-1 - MIVV exhausts

- STRONGER Cross line - MIVV ispuh

- STRONGER Enduro line - MIVV ispuh

- SUONO linija - MIVV ispuh

- URBAN linija - MIVV ispuh

- Pokrivači ispuha RMS

- STORM

- Kabeli, crijeva i bendžo

- Ključanice i dodaci

- Kočnice

- Axial brake calipers ACCOSSATO

- Brake and Ccutch pumps ACCOSSATO

- Brake flanges ACCOSSATO

- Brake/Clutch Fluid Reservoir BREMBO

- CNC oil tanks ACCOSSATO

- Čeljusti kočnica (pakne)

- Disk pločice

- Brake pads ACCOSSATO

- Disk pločice prednje

- BREMBO Disk pločice prednje G

- BREMBO Disk pločice prednje OFF-ROAD

- BREMBO Disk pločice prednje Road

- Disk pločice prednje Carbone Lorraine

- Disk pločice prednje GOLDFREN

- Disk pločice prednje GOLDFREN - prekinuti spojevi

- EBC Disk pločice prednje OFF-ROAD

- EBC Disk pločice prednje SCOOTER

- EBC Disk pločice prednje STREET

- EBC Disk pločice prednje STREET SINTERED

- EBC Disk pločice prednje TRACK / RACE USE

- Disk pločice straga

- BREMBO Disk pločice straga G

- BREMBO Disk pločice straga OFF-ROAD

- BREMBO Disk pločice straga ROAD

- Brake pads for parking brake EBC

- Disk pločice straga Carbone Lorraine

- Disk pločice straga GOLDFREN

- Disk pločice straga GOLDFREN - prekinuti spojevi

- EBC Disk pločice straga OFF-ROAD

- EBC Disk pločice straga SCOOTER

- EBC Disk pločice straga STREET

- EBC Disk pločice straga STREET SINTERED

- EBC Disk pločice straga TRACK / RACE USE

- Kočione pločice RMS

- Klinovi kočionih pločica TOURMAX

- Kočioni diskovi

- "Oversize" prednji kočioni diskovi EBC - supermoto

- '' Oversize '' prednji kočioni diskovi EBC - offroad

- Brake disc bolts front EBC

- Brake disc bolts rear EBC

- Brake discs front racing NG

- Disk prednje kočnice "oversize" NG

- Disk stražnje kočnice "oversize" NG

- Floating brake discs front NG

- Floating brake discs rear NG

- Kočioni diskovi prednji EBC - Harley Davidson

- Kočioni diskovi prednji EBC - Vintage

- Kočioni diskovi prednji JT

- Kočioni diskovi prednji NG

- Kočioni diskovi prednji RMS

- Kočioni diskovi skuteri GOLDFREN

- Kočioni diskovi straga EBC - Harley Davidson

- Kočioni diskovi straga EBC - Vintage

- Kočioni diskovi straga EBC - offroad

- Kočioni diskovi straga EBC - street

- Kočioni diskovi straga EBC - vee

- Kočioni diskovi straga JT

- Kočioni diskovi straga NG

- Kočioni diskovi straga RMS

- Kočni diskovi prednji EBC - offroad

- Kočni diskovi prednji EBC - street

- Kočni diskovi prednji EBC - vee

- Kočni bubnjevi RMS

- Kočni cilindri RMS

- Plastic oil tanks ACCOSSATO

- Poklopac rezervoara za kočnico PUIG

- Poklopac rezervoara za kvačilo PUIG

- Racing kits ACCOSSATO

- Radial brake calipers ACCOSSATO

- Rezervoari kočione tekućine MOTION STUFF

- Set za popravak kočnice (brtve u kompletu)

- Brtve ATV bubanj kočnice All balls

- Brtve kočionih cilindara RMS

- Pribor za pričvršćivanje kočione pločice All Balls

- Set za obnavljanje cilindara kotača All Balls

- Set za popravak

- Set za popravak cilindra kočnice All Balls

- Set za popravak cilindra poluge kvačila All Balls

- Set za popravak glavnog cilindra kocnice

- Set za popravak kočionih cilindara TOURMAX

- Koferi i prtljaga

- Assemble kits CUSTOMACCES

- Bags 70ty

- Dodaci za kofere SHAD

- Dodaci za prtljagu CUSTOMACCES

- Koferi CUSTOMACCES

- Koferi PUIG

- Koferi SHAD

- Komunikacijski uređaji SHAD - Intercoms

- Kožne toorbe CUSTOMACCES

- Nosači CUSTOMACCES

- Nosači kofera SHAD

- Nosači za pametne telefone / GPS SHAD

- TERRA cases and bags kits SHAD

- Torbe SHAD

- Torbe za alat CUSTOMACCES

- Tvrde bočne torbe CUSTOMACCES

- Motor

- Bottom end kits HOT RODS

- Bregasti remeni

- Čepovi za ispuštanje ulja

- Cilindar i dodaci

- Big bore cylinder kits CYLINDER WORKS

- Cilindar kitovi RMS

- Cilindar seti AOKI

- Cilinder kiti VERTEX

- Cilinder set ATHENA

- Cylinder head kits CYLINDER WORKS

- Cylinder kits TNT MPA

- Easy cilinder kit ATHENA

- Glave cilindra RMS

- Power valve kits CYLINDER WORKS

- Standard bore HC cylinder kits CYLINDER WORKS

- Standard bore cylinder kits CYLINDER WORKS

- Deli odmičnih gredi HOT CAMS

- Bregasto vratilo unicam HOT CAMS

- Dijelovi bregastog vratila HOT CAMS

- Instalacijski setovi HOT CAMS

- Ispuh bregastog vratila HOT CAMS

- Nečujni kompleti lanaca bregastog vratila HOT CAMS

- Podloške (shims) HOT CAMS

- Set bregastog vratila HOT CAMS

- Set upruga ventila HOT CAMS

- Set valjaka lanca bregastog vratila HOT CAMS

- Usisi bregastog vratila HOT CAMS

- Dihtunge

- Big Bore gasket kits CYLINDER WORKS

- Gaskets ARIETE

- O-rings ARIETE

- Pojedinačne brtve RMS

- Posamezna brtva Athena - single gaskets

- Seals ARIETE

- Set brtve motora RMS

- Set brtvi ATHENA cilinder kit

- Set dihtunga za motor ATHENA

- Set dihtunga za motor TOURMAX

- Standard bore gasket kits CYLINDER WORKS

- Top End set brtvi 4T offroad ATHENA

- VERTEX set brtvi (Winderosa)

- Brtve poklopca kvačila WINDEROSA

- Brtve poklopca motora VERTEX (Winderosa)

- Brtve ventila WINDEROSA

- Mehanički set za obnovu pumpe za vodu VERTEX (Winderosa)

- Set brtvi motora s VERTEX uljnim brtvama (Winderosa)

- Set ispušnih brtvi WINDEROSA

- Set uljnih brtvi motora (Winderosa)

- Set za obnovu vodene pumpe WINDEROSA

- Top End set brtvi VERTEX (Winderosa)

- VERTEX set brtvi (Winderosa)

- HD Unutarnji primarni ležajevi All Balls

- Klipnjača setovi

- Kvačilo

- BTL & Slipper clutches HINSON

- Backing Plates HINSON

- Billetproof Baskets HINSON

- Billetproof Inner Hubs HINSON

- Billetproof Pressure Plates HINSON

- Clutch Covers HINSON

- Clutch hubs VERTEX

- Cushion Kits for clutch baskets HINSON

- Cutch tool EBC

- Dijelovi kvačila RMS

- FSC Kit- Clutch Fiber Steel Springs HINSONS

- Hi-Temp Clutch Spring Kits HINSON

- Inner Hub & Pressure Plate Kit HINSON

- Košara kvačila

- Lamele kvačila MOTION STUFF

- Lamele kvačila VERTEX

- Oil filler caps HINSON

- Plate Kits- Fiber HINSON

- Plate Kits- Steel HINSON

- Set kvačila EBC

- Set metalnih ploča kvačila LUCAS

- Set metalnih ploča kvačila MOTION STUFF

- Set opruge kvačila EBC

- Set opruge kvačila LUCAS

- Set opruge kvačila MOTION STUFF

- Set ploča kvačila (lamele) EBC

- Set ploča trenja kvačila LUCAS

- Set za popravak hidravličnog kvačila

- Set za popravak kvačila EBC

- Tools HINSON

- Unutarnje košare kvačila AOKI

- Various HINSON

- Lanac bregaste osovine i pribor

- Mjenjač

- Oljna pumpa

- Piaggio gumeni dijelovi za motor RMS

- Pojedinačni ležajevi za motor RMS

- Poklopci motora RMS

- Radilica i pribor

- Rezervni dijelovi

- Set za obnovu motora WRENCH RABBIT

- Seti klipova in dodaci

- Go kart pistons VERTEX

- Igličasti ležajevi ATHENA

- Klipni iglični ležajevi RMS

- Klipni prsten RMS

- Kovani klip set ATHENA

- Off Road pistons VERTEX

- PWC pistons VERTEX

- Set kovanih klipova 4T Athena S

- Seti klipa RMS

- Seti klipov Athena Cast-lite

- Seti klipova AOKI 2T MX

- Seti klipova AOKI 4T MX

- Seti klipova AOKI ostalo

- Street & Moped pistons VERTEX

- Street bike range VERTEX

- VERTEX ostali proizvodi

- Seti senzora WRENCH RABBIT

- Skid plates Titanium GPR

- Termostat i dijelovi

- Top End piston kits

- Transmission bearing kits HOT RODS

- Ventilatori hlađenja All Balls

- Ventili

- Vodena pumpa

- Zupčanici za starter RMS

- Odjeća i kacige

- Bubrežni pojasevi

- Čizme

- Goggles

- Hlače

- Hlače 70ty

- Jeans

- Kožne sportske hlače

- Offroad hlače

- Tekstilne avanturističke hlače

- Tekstilne ostale hlače

- Tekstilne touring hlače

- GMS EVEREST

- GMS HIGHWAY 3 WP BIG

- GMS HIGHWAY 3 WP LADY

- GMS HIGHWAY 3 WP MAN

- GMS HIGHWAY WP JUNIOR

- GMS STARTER LADY

- GMS STARTER MAN

- GMS TERRA ECO WP

- GMS TRACK LIGHT (kalhoty)

- GMS TRENTO KIDS

- GMS TRENTO LADIES

- GMS TRENTO MAN

- YOKO BULSA pants

- YOKO JATKA pants

- YOKO JATKA pants - 2022 collection

- iXS ANNA-ST 2.0

- iXS NAIROBI-ST 2.0

- iXS SPACE-ST

- iXS TOUR-ST 1.0

- iXS Tromsö-ST 2.0

- Jakne

- Jakne 70ty

- Kožne klasične jakne

- Kožne sportne jakne

- Tekstilne avanturističke jakne

- Tekstilne ljetne jakne

- Tekstilne ostale jakne

- Tekstilne sportske jakne

- Tekstilne touring jakne

- GMS EVEREST (bundy)

- GMS GEAR LADY

- GMS GEAR MAN

- GMS GEAR WP JUNIOR

- GMS TAYLOR

- GMS TAYLOR LADY

- GMS TEMPER

- GMS TERRA ECO WP (bundy)

- GMS TIGRIS WP

- GMS TWISTER NEO WP LADY

- GMS TWISTER NEO WP MAN

- YOKO BULSA jackets

- YOKO BULSA jackets - 2022 collection

- YOKO JATKA jackets

- YOKO JATKA jackets - 2022 collection

- Kacige

- Dječje kacige

- Dualsport kacige

- Flip up kacige

- Integralne kacige

- AXXIS HAWK SV EVO

- AXXIS HAWK SV

- AXXIS COBRA

- AXXIS DRAKEN

- AXXIS DRAKEN S

- AXXIS EAGLE SV

- AXXIS GP RACER

- AXXIS PANTHER SV

- CASSIDA APEX

- CASSIDA FIBRE

- CASSIDA INTEGRAL 3.0

- CASSIDA INTEGRAL GT 2.0

- CASSIDA INTEGRAL GT 2.1

- Integral kacige CASSIDA

- MT Blade 2 SV

- MT Braker

- MT JARAMA

- MT KRE

- MT KRE+ Carbon

- MT Rapide

- MT Revenge

- MT Revenge 2

- Revenge 2 Baye MT

- Revenge 2 Chrono MT

- Revenge 2 GARZO MT

- Revenge 2 KLEY MT

- Revenge 2 Light MT

- Revenge 2 MTFOUNDATION MT

- Revenge 2 Moto 3 MT

- Revenge 2 RS MT

- Revenge 2 S Acosta MT

- Revenge 2 S Hatax MT

- Revenge 2 S Light MT

- Revenge 2 S Moreira MT

- Revenge 2 S Sergio Garcia MT

- Revenge 2 S Solid MT

- Revenge 2 Scalpel MT

- Revenge 2 Sergio Garcia MT

- Revenge 2 Skull & Roses MT

- Revenge 2 Solid MT

- Revenge 2 Xavi Vierge MT

- MT STINGER

- MT Targo

- Targo Bee MT

- Targo Crazydog MT

- Targo Doppler MT

- Targo Enjoy MT

- Targo Interact MT

- Targo Joker MT

- Targo PRO Biger MT

- Targo PRO Podium MT

- Targo PRO Sound MT

- Targo PRO Welcome MT

- Targo Podium MT

- Targo Rigel MT

- Targo S Britain MT

- Targo S Joke MT

- Targo S Kay MT

- Targo S Solid MT

- Targo Solid MT

- Targo Truck MT

- MT Thunder 3 SV Full Face

- MT Thunder 4 SV Full Face

- Thunder 4 SV Cheep MT

- Thunder 4 SV DRAX MT

- Thunder 4 SV ERGO MT

- Thunder 4 SV EXEO MT

- Thunder 4 SV Fade MT

- Thunder 4 SV JUNGLE MT

- Thunder 4 SV Jerk MT

- Thunder 4 SV MIL MT

- Thunder 4 SV MOUNTAIN MT

- Thunder 4 SV PENTAL MT

- Thunder 4 SV R25 MT

- Thunder 4 SV Solid MT

- Thunder 4 SV TREADS MT

- Thunder 4 SV Valiant MT

- iXS 216

- iXS 422

- Kacige SHIRO

- Offroad kacige

- Otvorene kacige

- CASSIDA JET HANDY

- AXXIS HORNET SV

- AXXIS METRO

- AXXIS MIRAGE SV

- AXXIS RAVEN SV

- AXXIS SQUARE

- CASSIDA JET TECH

- CASSIDA MAGNUM

- CASSIDA OXYGEN

- CASSIDA REFLEX

- MT Avenue

- MT Cosmo SV

- MT Le Mans 2 SV

- Le Mans 2 SV Anarchy MT

- Le Mans 2 SV Cafe Racer MT

- Le Mans 2 SV Diler MT

- Le Mans 2 SV Divenire MT

- Le Mans 2 SV Extreme MT

- Le Mans 2 SV Flaming MT

- Le Mans 2 SV Hardcore MT

- Le Mans 2 SV Hipster MT

- Le Mans 2 SV Love MT

- Le Mans 2 SV Numberplate MT

- Le Mans 2 SV Outlander MT

- Le Mans 2 SV S Breakout MT

- Le Mans 2 SV S Luther MT

- Le Mans 2 SV S Quality MT

- Le Mans 2 SV S Solid MT

- Le Mans 2 SV Skull & Roses MT

- Le Mans 2 SV Solid MT

- Le Mans 2 SV Tant MT

- Le Mans 2 SV Zero MT

- MT Le Mans SV

- MT Lite

- MT Street

- MT Thunder 3 SV

- MT Viale SV

- iXS 92

- Spare parts and accessories of helmets

- Trial i streetfighter kacige

- Kevlar clothes

- Kišna odjeća

- MX Jerseys

- Motorcycle overalls

- Odjeća AYRTON

- Odjeća za slobodno vrijeme

- Potkape

- Protectors

- Rukavice

- Set of MX pants and MX jersey

- Vests

- Plastika

- Handguards POLISPORT

- Brake cooler PUIG

- Dodaci POLISPORT

- Engine cover protections POLISPORT STREET

- Fork boots ARIETE

- Karbonski zaštite poklopaca motora PUIG

- Nastavci bokobrana PUIG

- Nastavci prednjih bokobrana PUIG

- Nastavci stražnjih bokobrana PUIG

- PERFORMANSE dijelovi i pribor POLISPORT

- Gorjna zaštita vilica POLISPORT

- Mrežice za zaštitu hladnjaka POLISPORT

- PDS Protectors POLISPORT

- Spremnici za gorivo PROOCTANE POLISPORT

- Štitnici poklopca kvačila POLISPORT

- Štitnici poklopca za paljenje POLISPORT

- Štitnici za diskove i donje vilice POLISPORT

- Štitnici za donje vilice POLISPORT

- Vodilica lanca POLISPORT

- Zaštita hladnjaka POLISPORT

- Zaštita motora POLISPORT

- Zaštita okvira POLISPORT

- Zaštita prigušivača POLISPORT

- Zaštita zadnje vilice (vaga) POLISPORT

- Prednja svjetla POLISPORT

- Prednji blatobran PUIG

- Rear number plates ARIETE

- Rear seat cowls PUIG

- Replacement plastics

- Replika plastike POLISPORT

- Airboxes POLISPORT

- Bočna plastika + poklopac filtra za zrak POLISPORT

- Bočna plastika POLISPORT

- Brake hose guides POLISPORT

- Clutch and ignition cover protector kits POLISPORT

- Front sprocket protectors POLISPORT

- Klizač i vodilica lanca - komad POLISPORT

- Klizač i vodilica lanca POLISPORT

- Klizač lanca - komad POLISPORT

- Klizač lanca POLISPORT

- Plastika brojeva POLISPORT

- Plastika rezervoara POLISPORT

- Plastika uz hladnjak i rezervoar POLISPORT

- Prednja plastika POLISPORT

- Prednji blatobrani POLISPORT

- Štitnici za diskove POLISPORT

- Štitnici za vilice POLISPORT

- Stražnji blatobrani + bočna plastika POLISPORT

- Stražnji blatobrani POLISPORT

- Vodilica lanca POLISPORT

- Waterpump protectors POLISPORT

- Zaštita ispušne krivine POLISPORT

- Zaštita stražnjeg amortizera POLISPORT

- Set plastika POLISPORT

- Single swing arm fenders PUIG

- Stajala za motore POLISPORT

- Stražnja svjetla POLISPORT

- Stražnji blatobrani PUIG

- Tepisi za motore POLISPORT

- Univerzalna plastika

- Zaštita poklopca motora PUIG

- Zaštita za ruke PUIG

- Prijenos (Lanci, Lančaniki, Jermeni)

- Chain tensioners PUIG

- Gumeni ublaživaći

- Lančanici

- Lanci

- Chains D.I.D

- Lanac EK

- BARVNI lanac EK - Racing series - Chains for the toughest race conditions

- Chains EK - 3D High performance chains

- Lanci EK - DEX series - QX-ring chains for light bikes and enduros

- Lanci EK - Heavy duty series

- Lanci EK - MVXZ series - MANUFACTURER-QUALITY chains for 600cc-1000cc motorcycles

- Lanci EK - Racing series - Chains for the toughest race conditions

- Lanci EK - SRO series - High-quality O-ring chains at affordable prices

- Lanci EK - SRX series - The most-used chains for all motorcycles

- Lanci EK - ZVX series - The strongest chains ideal for extreme sportbikes

- Lanci KMC

- Osovina mjenjača

- Pogonski remen MITSUBOSHI

- Pogonski remeni

- Pogonski sklop PIAGGIO ORIGINAL OE

- Rolice All Balls

- Set Lanac i lančanici

- EC i SUPERSPROX set lanaca - OBRADA - do 10% veće kilometraže

- Set lanaca D.I.D i JT

- Set lanaca D.I.D i JT - PRETVORBA

- Set lanaca D.I.D i SUPERSPROX - OBRADA - do 10% veće kilometraže

- Set lanaca D.I.D i SUPERSPROX - do 10% veće kilometraže

- Set lanaca EK i JT

- Set lanaca EK i JT - PRETVORBA

- Set lanaca EK i SUPERSPROX - do 10% veće kilometraže

- Transmition products OE

- Varijator i dijelovi

- Klizači varijatora RMS

- Kompleti remenica RMS

- Poklopac variatora RMS

- Remenice varijatora RMS

- Valjci s varijacijskim kompletom - za originalni varijator

- Valjci variatora RMS

- Variator rollers Premium BANDO

- Varijatori ATHENA

- Variomati dijelovi J.Costa PRO

- Alat za variomate J.Costa

- Belts J.Costa

- Klizači J.Costa

- Kvačilo J.Costa

- Kvačilo ploče J.Costa

- Piksna J.Costa

- Pulley J.Costa

- Remenje J.Costa

- Spare parts J.Costa

- Transmission kits J.Costa

- Valjci J.Costa

- 10 rollers (20mm) for J.Costa

- 10 valjaka (25 mm) za J.Costa

- 12 valjaka (25 mm) za J.Costa

- 14 valjaka (31 mm) za J.Costa

- 16 valjaka (31 mm) za J.Costa

- 16 valjaka (34 mm) za J.Costa

- 17 valjaka (31 mm) za J.Costa

- 17 valjaka (34 mm) za J.Costa

- 17 valjaka (38 mm) za J.Costa

- 9 valjaka (25 mm) za J.Costa

- Valjci ostali J.Costa

- Variomati J.Costa PRO

- Variomati J.Costa XRP

- Vijaki za lančanik MOTION STUFF

- Zaštita lanca PUIG

- Proizvodi po narudžbi

- Bočni stalci JMT

- Brave setovi JMT

- Carburettor float set TOURMAX

- Carburettor jets

- Crash barovi FEHLING

- Crash bungs LSL

- Fairing windshields MRA

- Float needles TOURMAX

- Grijane ručke (gripovi)

- Kineski skuteri dijelovi

- Komplet mijehova

- Kondenzatorske jedinice TOURMAX

- Navlake za motore JMP

- Neutralni prekidači TOURMAX

- Nogare (Footrests)

- Oljna pumpa

- Plastični vijci, zakovice, pričvršćivači

- Pločice za podešavanje ventila

- Pumpe za gorivo

- Razni električni dijelovi

- Rezervoari kočione tekućine TOURMAX

- Ručke (gripovi) JMT

- Set za montažu radijatora

- Seti za podizanje straga LUCAS

- Seti za spuštanje straga LUCAS

- Setovi za popravak TOURMAX

- Tankpadi i naljepnice

- Usisno koljeno karburatora

- Ventili motora JMT

- Ventili za odzračivanje vilica JMP

- Vijak za ulje

- Vijci, matice, čepovi

- Vodootporne navlake za sjedala JMS

- Vreće za prijevoz guma JMT

- Zaštita rezervoara JMP

- Zatezač razvodnog lanca

- Retrovizorji

- Ručice kočnice i kvačila, stopalke i kontrole

- Brake foot pedals PUIG

- Brake lever protectors PUIG

- Brake levers MOTION STUFF

- Brake pedals MOTION STUFF

- CNC brake and clutch levers ACCOSSATO

- Clutch cable-hydraulic conversion kits ACCOSSATO

- Clutch lever protectors PUIG

- Clutch levers ACCOSSATO

- Clutch levers MOTION STUFF

- Fixed levers for original system ACCOSSATO

- Folding levers for original system ACCOSSATO

- Footrest racing ACCOSSATO

- Gear shift pedals PUIG

- Gearshift levers MOTION STUFF

- Kick start levers CUSTOMACCES

- Kompletne poluge RMS

- Lever guards ACCOSSATO

- Levers ProTaper

- Nogare (Footrests) CUSTOMACCES

- Nožni starter i dijelovi nosača RMS

- Offroad footrests ACCOSSATO

- Original type replacement levers ACCOSSATO

- Pedale sovozača PUIG

- Pedale vozača PUIG

- Poklopne ručice WRP

- Poluge RMS

- Poluge za plin kompletirane RMS (Domino)

- Replacement levers ACCOSSATO

- Rubber for hand levers ARIETE

- Ručica mjenjača

- Ručice Off-road PUIG

- Ručice kočnica JMT

- Ručice kočnica PUIG - TÜV odobrenje

- Ručice kvačila JMT

- Ručice kvačila PUIG - TÜV odobrenje

- Ručice mjenjača JMT

- Scooter levers PUIG

- Throttle controls ACCOSSATO

- Unbreakable levers POLISPORT

- VENHILL twistgrips

- WRP proizvodi za MX

- Šasija

- Adjuster closer cap kits BITUBO

- Buffers ARIETE

- Clamp steering kits BITUBO

- Fork seals kit Bycicle SKF

- Fork valves kit BITUBO

- Full kits BITUBO

- Gumeni nastavci TOURMAX

- Komplet osovine stražnjeg kotača RMS

- Komponente ovjesa

- Decals KYB

- Dijelovi za podešavanje K-TECH

- Setting parts KYB

- Spare parts K-tech

- Za prednju vilicu

- Accessories YSS

- Bleeder set for front forks MOTION STUFF

- Brtve proti prašini K-TECH

- Brtve vilica ATHENA

- Brtve vilica All Balls

- Brtve vilice K-TECH

- Cijevi vilice

- Dust seals ARIETE

- Dust seals K-TECH - package

- FF Dust seals KYB

- FF Oil Seals KYB

- FF sliding kit BITUBO

- FF spring guides K-TECH

- Fork Seals ONLY 1 seal! SKF

- Fork and Dust Seal (1 pc each) SKF

- Fork bushing kit (1 guide 1 slide ) SKF

- Fork caps ARIETE

- Fork gaiters ARIETE

- Fork seals ARIETE

- Fork seals BITUBO

- Fork seals K-TECH - package

- Fork service kit KYB

- Fork springs BITUBO

- Fork springs KYB

- Forks BITUBO

- Front fork Factory kits KYB

- Front fork cartridge BITUBO

- Front suspension parts ARIETE

- KYB FF Parts Off Road K-TECH

- KYB FF Parts Road K-TECH

- Klinovi ovjesa RMS

- Klipni setovi K-TECH

- Klizne čahure K-TECH

- Opruge vilica K-TECH

- Other parts for front fork K-TECH

- PD FORK VALVE YSS K-TECH

- PD fork valves YSS

- Poluga upravljača RMS

- Progresivne opruge prednjih vilica YSS

- Racing parts KYB

- SHOWA FF Parts Off Road K-TECH

- SHOWA FF Parts Road K-TECH

- Set za popravak ležajeva vilica

- Setovi za zaštitu vilica MOTION STUFF

- Spare parts front fork KYB

- Stupovi upravljača RMS

- Uložak prednjih vilica K-TECH

- Ventili za protok zraka K-TECH

- Vodeće čahure K-TECH

- X-TRIG

- Za stražnji amortizer

- Dodaci amortizera RMS

- HPTP K-TECH

- KYB RCU Parts Off Road K-TECH

- Ležaj amortizera ALL BALLS

- Mounting parts YSS for assembling

- Other parts for shock absorber K-TECH

- Prigušne opruge K-TECH

- Progresivne stražnje amortizerske opruge YSS

- RCU Dust seals KYB

- RCU Oil Seals KYB

- RCU Piston bushes (SPB) K-TECH

- RCU uljne brtve (za stražnji amortizer) K-TECH

- RCU vodeće čahure K-TECH

- Rear shock Factory kits KYB

- Rear shock repair kits (SASK) K-TECH

- Rear suspension parts ARIETE

- SHOWA RCU Parts Off Road K-TECH

- SHOWA RCU Parts Road K-TECH

- Seals other SKF

- Set za popravak stražnjeg amortizera All balls

- Shock absorber pistons K-TECH "

- Shock items SKF

- Shock springs KYB

- Spare parts rear shock KYB

- Twin dampers YSS for assembling

- Twin springs YSS for assembling

- YSS rezervni dijelovi

- Linkage parts K-TECH

- Naljepnice RMS

- Obruči kotača RMS

- Osi All Balls

- Other Piaggio parts OE

- Piaggio dijelovi karoserije RMS

- Pojedinačni vijci, matice i stezaljke RMS

- Prednja vilica Racing K-TECH

- Pričvršćivači MOTION STUFF

- Rubber parts ARIETE

- Set kolesnih vijakov in matic All Balls

- Set matica kotača All Balls

- Seti ležajeva

- ATV CV Boot Kits All Balls

- ATV kuglični zglobovi All Balls

- ATV ležajevi diferencijala ALL BALLS

- Front wheel seals kit with spacer and bearing SKF

- Ležajevi i semerinzi volana ALL BALLS

- Ležajevi kotača ALL BALLS

- Ležajevi nihajne ruke ALL BALLS

- Pojedinačni ležajevi za šasiju RMS

- Rear wheel seals kit with spacer and bearing SKF

- Ručke (Gripi) RMS

- Servisni set za povezivanje karika njihalice (vaga) ALL BALLS

- Set ATV ležajeva A-ruke ALL BALLS

- Set krajnika All Balls

- Set ležajeva za stražnjog pedala KTM

- Set odstojnika All Balls

- U-zglobni i viličasti sklopovi All Balls

- Wheel bearings FRONT SKF

- Wheel bearings Rear SKF

- Spare springs kit BITUBO

- Springs and caps kit BITUBO

- Stajala za motore

- Steering dampers BITUBO

- Steering dampers K-TECH

- Stražnji amortizer

- Wheel seals SKF

- Sjedala i dodaci

- Sustav goriva

- Cijevi i priključci za gorivo / ulje RMS

- Filteri goriva

- Fuel pumps All Balls

- Poklopac goriva za rezervoar RMS

- Poklopac rezervoara za utrku PUIG

- Pumpe za gorivo RMS

- Reparatur set karburatora All Balls

- Set za obnovu pumpe za ubrzanje All Balls

- Set za popravak pipice za gorivo All Balls

- Set za popravak ventila AirCut All Balls

- Set za popravak ventila spremnika goriva

- Vakum ventil RMS

- Ventili za gorivo i stezaljke za crijeva FUEL STAR

- Ulje i maziva

- Braking oils ACCOSSATO

- Chain care products D.I.D.

- Filter care BMC

- KYB ulje za suspenziju

- MAGURA tekučine

- Maziva - SILKOLEN

- 2T Motorna Ulja SILKOLENE

- 4T Motorna olja SILKOLENE

- Aditivi za gorivo - SILKOLENE

- Olja za amortizere SILKOLENE

- Proizvodi za održavanje lanca - SILKOLEN

- Proizvodi za održavanje zračnih filtera - SILKOLENE

- Rashladne tekućine SILKOLEN

- Scooter ulja SILKOLENE

- Servisni proizvodi - SILKOLENE

- Sredstva za čišćenje - SILKOLEN

- Tekućina za kočnice i za kvačilo SILKOLEN

- Ulja za prijenos SILKOLEN

- Maziva za motocikle Bel-Ray

- 2T - motorna ulja - 1L - Bel-Ray

- 2T - motorna ulja - 20L - Bel-Ray

- 2T - motorna ulja - 355ML - Bel-Ray

- 4T - motorna ulja - 1L - Bel-Ray

- 4T - motorna ulja - 208L - Bel-Ray

- 4T - motorna ulja - 4L - Bel-Ray

- 4T - motorna ulja - 60L - Bel-Ray

- Proizvodi za servis - Bel-Ray

- Rashladne tekućine - 1L - Bel-Ray

- Spreji za negu lanaca - Bel-Ray

- Tekućina za kočnice - Bel-Ray

- Ulja i sredstva za čiščenja filtera - Bel-Ray

- Ulje za menjače - 1L - Bel-ray

- Ulje za vilice - 1L - Bel-Ray

- V-Twin ulja - 4L - Bel-Ray

- V-Twin ulja - 955ML - Bel-Ray

- Moto cosmetics RMS

- Moto program ulja i maziva ENEOS

- Motorcycle lubricants KYB

- Oils and lubricants KETTENMAX

- Suspension fluids K-TECH

- Tekućina za kočnice BREMBO

- Tekućina za kočnice EBC

- Ulja i maziva za nautiku - Bel-Ray

- Ulje i maziva JMC

- Upravljači (volani) za motocikle

- Bar risers PUIG

- Clip-On handlebar kits ACCOSSATO

- EASTON gripi

- EASTON pribor

- EASTON upravljači - sistem EXP 1 1/8 - 28,6mm

- EASTON upravljači - sistem EXP 1 3/8" - 35mm

- Grips (not lock-on) ODI

- Grips ARIETE

- Handlebars and accessories ACCOSSATO

- Krajevi upravčjača (volana) MOTION STUFF

- Lock-on grips ODI

- Plastika upravljača RMS

- Ručke (Gripi) CUSTOMACCES

- Ručke (Gripi) MOTION STUFF

- Ručke (Gripi) PUIG

- Ručke (Gripi) ProTaper

- Ručke (Gripi) RMS

- Upravljači (volani) CUSTOMACCES

- Upravljači (volani) PUIG

- Upravljači (volani) ProTaper

- Utez za volan PUIG

- Volanska ojačanja PUIG

- WRP upravljači (volani) za motocikle

- Vjetrobranskih stakala, fairings, spojleri

- Semifairing PUIG

- Bočne ploče PUIG

- Bočne stranice radijatora PUIG

- Cafe Racer maske PUIG

- E.R.S. sustavi za vjetrobranska stakla PUIG

- Exhaust protectors PUIG

- Faco vjetrobranska zaštita RMS

- M.E.M. sustavi zaštite vjetrobranskog stakla PUIG

- Nosači vjetrobranskog stakla PUIG

- Poklopac - deflektori PUIG

- Retrovizori PUIG

- Spojler-ralica PUIG

- Vizir - prilagodljiv PUIG

- Vizir za custom motore PUIG

- Vizir za skutere PUIG

- Vizir-nizki za okruglo svijetlo PUIG

- Vizir-visoki za okruglo svijetlo PUIG

- Vjetrobrani for fairing bikes PUIG

- Vjetrobrani specific for non-round headlights PUIG

- Vjetrobrani univerzalni PUIG

- Vjetrobrani za maxiscootere PUIG

- Vjetrobranska stakla CUSTOMACCES

- Windshields retro - vintage PUIG

- Zaštita hladnjaka CUSTOMACCES

- Zaštita hladnjaka PUIG

- Zaštita svijetla PUIG

- Zaštita za svijetla CUSTOMACCES

Novi proizvodi u sustavu

WE WILL PROSECUTE ALL INTERNET THEFT OF OUR COPYRIGHTED MATERIAL. DO NOT COPY OUR CONTENT.